HVOF Coating Services

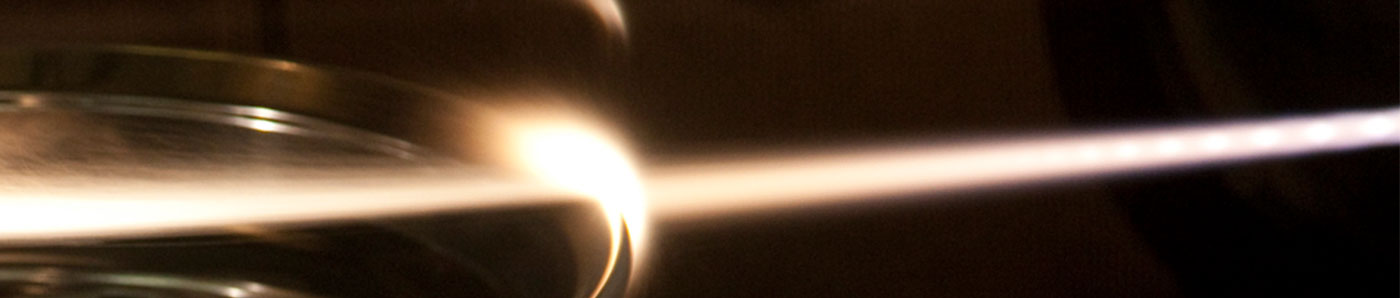

High Velocity Oxy Fuel Coating Services

Praxair Surface Technologies invented the high velocity oxy fuel (HVOF) coating process to produce dense coatings that protect against erosion, abrasion and chemical attack. The process can be uniquely controlled by the fuel, material, speed, temperature, distance and angle of deposition, resulting in the high-density coating strongly bonding with repeatable composition, structure and properties.

Typical thickness of HVOF thermal spray coatings ranges from 0.002 to 0.020 inches (50 to 500 µm), and as-deposited surface roughness may exceed 100 µin (2.5 µm) Ra. HVOF thermal spray coatings may also be used as deposited or ground and lapped to meet your needs. HVOF thermal spray coatings can provide resistance to erosion, abrasion and chemical attack.

Like any other thermal spray, HVOF deposition is a line-of-sight process. The best coating properties are usually achieved when the angle of deposition is close to 90 degrees to the part surface. As the angle of deposition decreases to less than 45 degrees, significant changes occur in the coating microstructure and properties. Nonetheless, coatings made at lower deposition angles may be useful and are highly reducible.

PST also has developed Advanced HVOF thermal spray coatings, including:

- CoreGardTM Inner Diameter Coatings

- ExoGardTM Dense, Thin and Smooth Coatings