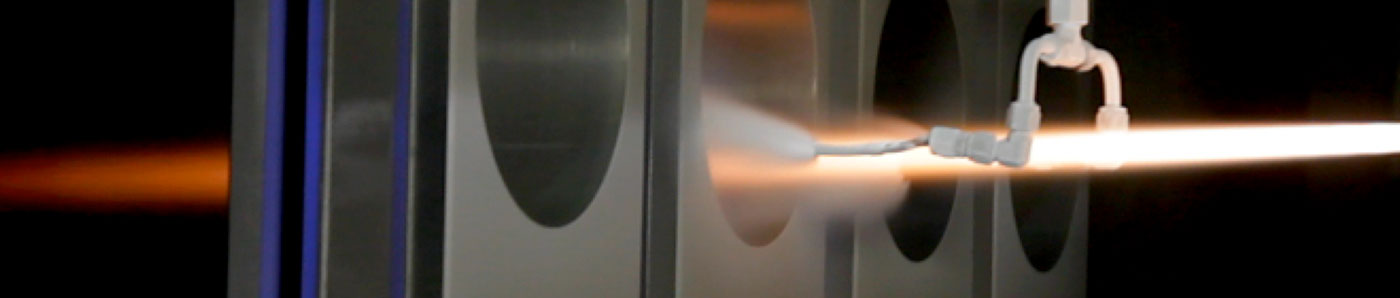

Thermal Spray coating services

Thermal Spray Coating - An Effective Process from Every Angle

Thermal spray coating is a cost-effective way to protect critical components from wear, corrosion, fatigue, oxidation and high temperatures. It can be used to extend the service life and improve performance of new parts before they go into operation, as well as restore worn parts.

Our versatile thermal spray coating processes can apply a wide range of materials at different spray rates and coating thicknesses to meet your unique specifications. With our multi-axis robots and automated systems, we can create uniform thermal spray coatings on the most complex of geometries, delivering a high quality coating that can withstand the harshest operating environments. High temperature oxides, tungsten-carbide, chromium-carbide and copper-nickel-indium are just a few of the materials we can apply using one of our thermal spray technologies. See our different services for thermal spray applications below.

Cold Spray Coating Services

Detonation Gun & Super D-Gun™ Thermal Spray Coating Services

Flame Spray Coating Services

High-Velocity Oxy Fuel (HVOF) Thermal Spray Coating Services

Advanced HVOF: CoreGardTM Thermal Spray Coatings

Advanced HVOF: ExoGardTM Thermal Spray Coatings

Plasma Spray (including LPPS, Shrouded & SPS) Coating Services

Wire Arc Spray Coating Services

What is thermal spray coating?

Thermal spray coating is a category of the coating services in which a material is melted down and then applied to a substrate as a spray of molten or semi-molten droplets which form the protective coating, in order to improve functional performance. Thermal spray coatings are commonly used in manufacturing, specifically in the manufacture of gas turbines, diesel engines, bearings, processing equipment and coating medical implants.

Benefits of Thermal Spray Coating

- Almost any material can be used for thermal spray coating as long as it melts or becomes plastic during the spray coating process. Materials such as metals, alloys, ceramics, carbides, polymers and plastic are all ideal for thermal spray coating.

- Thermal spray coatings can be applied manually or by machine and have a high deposition rate.

- Thermal spray coating allows for the spraying of coating material with a higher melting point than the substrate.

- When coupled with premium spray material, the thermal coating process can extend the lifetime performance of new components

- Thermal spray coating allows parts to be rebuilt quickly and at low cost