- Overview of metal AM powders

- questions for your powder supplier

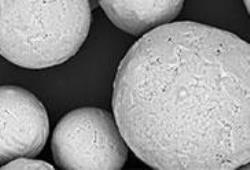

- how metal am powders are made

- Tru2Spec Precision Powder Formulation

- TruForm Product Portfolio

questions for your Metal am powder supplier

8 Questions for your Additive Manufacturing metal powder suppliers

Whether your organization is working in prototypes or mass production of metal AM parts, here are eight important qualities to consider in any AM metal powders supplier. We'll also share how Praxair Surface Technologies is positioned in each of these areas to help your operation meet the demands of metal AM.

AM Metal Powders Buyers Guide(488KB)

Can your metal powder supplier pour thousands of pounds in one melt? We have the capacity to produce lot sizes that are thousands of lbs., while maintaining a high yield percentage in both coarse and fine grain particles.

Can your supplier tailor their powders to your projects? Praxair Surface Technologies manufactures both large and small lots, delivering powders in quantities as low as 10 lbs. We make metal powders optimized for all additive platforms and can also customize composition and sizing to your precise parameters. Praxair stocks standard products in large inventories for fast delivery. Customized products can be delivered in as little as a few weeks, not months.

Does your supplier specialize in only a few compositions? As your metal AM expertise grows, so may your needs for different materials. We manufacture and supply cobalt, copper, iron, nickel, and titanium powders at a mass-production scale.

What technology does your supplier use to manufacture its powders? Praxair Surface Technologies only produces metal powders using vacuum induction melting with argon gas atomization. We also built the world's largest titanium gas atomizer for high-volume production, which added to our existing large-scale production of cobalt, iron, and nickel powders. Our close-coupled atomization technology delivers up to 10x more yield vs. older methods.

Does your supplier have a proven track record in metal powder manufacturing safety? Like most manufacturing, AM metal powder production can be dangerous if not done correctly. We regularly consult with customers to help them improve and refine their safety procedures, building from best practices we've developed over decades of metal powder manufacturing.

Does your supplier carry the necessary certifications for your end-use? Praxair works with aerospace-grade raw materials which undergo thorough testing in our onsite lab. We carry AS 9100, ISO 9001, and Nadcap certifications.

Does your supplier implement formal process improvement methodologies? We employ Six Sigma, Lean Manufacturing, 5S, and other continuous improvement methodologies to keep our processes up-to-speed with the metal AM industry and devise process improvement products specific to metal AM.

Is your supplier committed to keeping pace with metal AM growth? We have been an industry leader and innovator since 1946. Our parent company, Linde plc serves more than a million customers worldwide and has annual sales of $28 billion. With this backing, Praxair Surface Technologies has made substantial, ongoing investments in metal AM.

metal powders for additive manufacturing

Tru2Spec Precision Powder Formulation

Precision AM metal powders

Precision AM metal powders

designed for your innovative applications

Tru2Spec™ precision powder formulation, only from Praxair, enables you to create a custom AM metal powder that meets the exact specifications of your most demanding applications. No more guessing if an off-the shelf powder will hit the spec and meet your requirements.

TruForm Metal Powders - Tru2Spec Brochure

How Tru2Spec™ works

1. Evaluate your custom powder before it's ever produced

- Collect application specifications such as operating environment, desired powder characteristics, and part production method

-

Develop powder formulations

- Create detailed powder profile and analysis such as chemistry profile, flowability measures and certifications specific to your requirement

2. Test powder performance in trial-sized batches

- Produce small lots for customer testing, verification and potential printing

- Refine powder formulations based on trial tests and conduct quality assessments to create larger project

3. Produce approved powder for commercial use

- Produce custom powder in lot sizes from 5 kg to 2,500 kg in a few weeks

Contact Praxair for more information on how we can provide the best products for your metal powder needs.

METAL POWDERS FOR ADDITIVE MANUFACTURING

Cobalt Metal Powders

|

PRODUCT NAME |

TYPICAL CHEMISTRY COMPOSITION |

SAFETY DATA SHEET (SDS) |

|

TruForm™ 188 |

Co-22Cr-22Ni-15W |

|

|

TruForm™ 509 (Co-222) |

Co-23Cr-10Ni-7W-4Ta |

|

|

TruForm™ CoCr (Co-538) |

Co-28Cr-6Mo-0.2C-0.2 |

CO-538 (138KB) |

Iron Metal Powders

|

PRODUCT NAME |

TYPICAL CHEMISTRY COMPOSITION |

SAFETY DATA SHEET (SDS) |

|

TruForm™ 15-5 (Fe-347) |

Fe-14Cr-4Ni-4Cu-0.3Nb |

|

|

TruForm™ 17-4 (Fe-276) |

Fe-16Cr-4Ni-3Cu-1Si-0.25Nb |

|

|

TruForm™ 316 (Fe-271) |

Fe-17Cr-12Ni-3Mo |

|

|

TruForm™ MS (Fe-339) |

Fe-18Ni-9Co-5Mo-1Ti |

Nickel Metal Powders

|

PRODUCT NAME |

TYPICAL CHEMISTRY COMPOSITION |

SAFETY DATA SHEET (SDS) |

|

TruForm™ 142 (Ni-365) |

Ni-12Co-7Cr-6Ta-6Al-5W-3Re-2Hf-2Mo-0.1C |

|

|

TruForm™ 230 (Ni-1287) |

Ni-22Cr-14W-2Mo |

|

|

TruForm™ 247 (Ni-335) |

Ni-10Co-10W-8Cr-6Al-3Ta-1Hf-1Ti-0.6Mo-0.2C |

|

|

TruForm™ 617 (Ni-1066) |

Ni-22Cr-12Co-9Mo-1Al-0.6C |

|

|

Ni-22Cr-10Mo-Nb+4Ta |

||

|

Ni-19Cr-18Fe-Nb+5Ta-3Mo-1Ti |

||

|

TruForm™ 738 (Ni-284) |

Ni-16Cr-9Co-3Al-3Ti-3W-2Mo-2Ta-0.9Nb-0.1C |

|

|

TruForm™ 914 (Ni-914) |

Ni 99.00 min |

NI-914 (113KB) |

|

TruForm™ 939 (Ni-238) |

Ni-22Cr-10Co-4Ti-2W-2Al-1Ta-1Nb-0.1C |

|

|

TruForm™ HX (Ni-111) |

Ni-22Cr-19Fe-9Mo-2Co-0.5W-0.1C |

NI-111 (132 KB) |

*Made under license for Haynes International

Hastelloy and Haynes are registered trademarks of Haynes International; Inconel is a registered trademark of Special Metals Corporation; MAR-M is a registered trademark of Martin Marietta; Rene is a trademark of GE Corporation

Titanium Metal Powders

| PRODUCT NAME | TYPICAL CHEMISTRY COMPOSITION | SAFETY DATA SHEET (SDS) |

| TruForm™ 64-5 (Ti-105) | Ti-6Al-4V (Grade 5) | TI-105 (155KB) |

| TruForm™ 64-23 (Ti-123) | Ti-6Al-4V (Grade 23) | TI-123 (155KB) |

| TruForm™ 4822 (Ti-4822) | Ti-48Al-2Nb-2Cr | Tl-4822 (136KB) |

| TruForm™ 6242 (Ti-301) | Ti-6Al-2Sn-4Zr-2Mo | N/A |

Our TruForm high-quality, gas atomized metal powders are specifically designed for additive manufacturing to support every part you make with capacity, quality, and experience.

Our TruForm high-quality, gas atomized metal powders are specifically designed for additive manufacturing to support every part you make with capacity, quality, and experience.