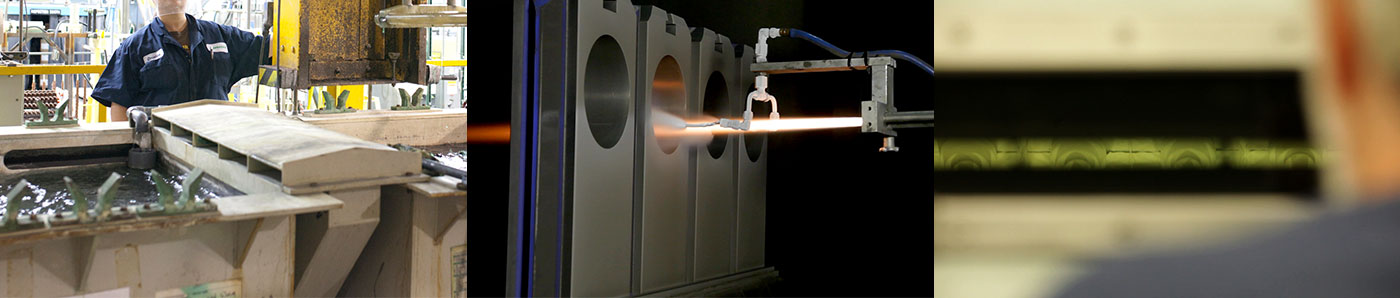

Our thermal spray processes are cost-effective and versatile, helping you protect new and worn parts from wear, corrosion, fatigue, oxidation and high temperatures.

Cold Spray, Detonation Gun (D-Gun), Super D-GunTM, Flame Spray, High Velocity Oxygen Fuel (HVOF), Advanced HVOF CoreGardTM, Advanced HVOF ExoGardTM, Plasma Spray (LPPS, Shrouded & SPS), and Wire Arc Spray

We offer a wide range of slurry processes designed to create stable coating films that are strongly bonded to the substrate of metal, ceramic and glass components.

SermAlcote®, SermaGard®, SermaLonTM, SermaLoyTM, & SermeTelTM

We offer three different vapor deposition processes to deliver the coating properties and structures you need on precision parts.

Cathodic Arc Physical Vapor Deposition (CAPVD), Chemical Vapor Deposition (CVD), & Electron Beam Physical Vapor Deposition (EBPVD)

We use the diffusion process to apply platinum, platinum aluminide and simple aluminide coatings on turbine airfoils and other components.

Diffused Slurry, Pack Diffusion, & Vapor Phase Diffusion

Along with laser case hardening and laser welding services, we offer a laser cladding process that produces weld overlays that are metallurgically bonded and virtually impenetrable.

Our electrodeposition process, TribometTM, is designed to maximize hardness of your most critical components, delivering corrosion, friction and wear resistance.